Bi-directional, autonomous zip line trolleys are setting a new benchmark for adventure and recreation operators. These advanced systems combine automation, energy recovery, and real-time data to deliver safer, more efficient, and more profitable zip line experiences. This article explores the core features, business advantages, and operational impact of automated zip line trolleys, helping you understand how they can elevate your facility.

The Power of Bi-Directional Autonomous Zip Line Trolleys

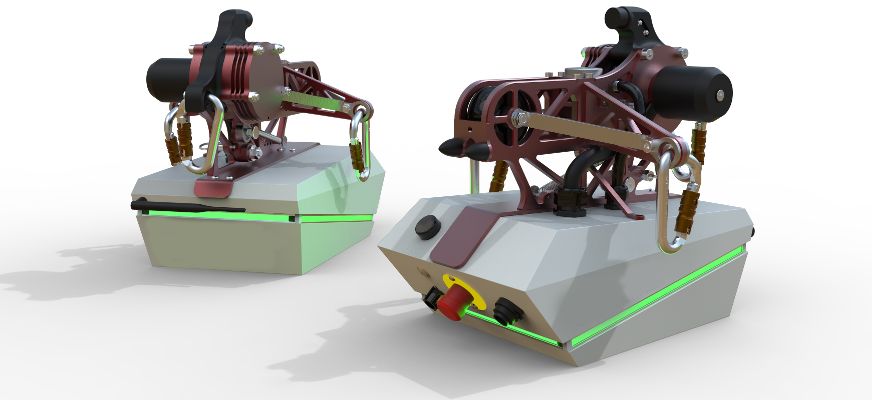

Bi-directional autonomous zip line trolleys are engineered to operate independently, adapting to site conditions and user needs. These mechatronic systems use advanced programming to regulate speed, ensure safe arrivals, and return to the starting point without manual intervention—now in both directions.

Key business advantages include:

-

Programmable operation for different site layouts and user profiles

-

Speed regulation for optimal safety and comfort

-

Guaranteed arrival at the end point, regardless of user weight or weather

-

Autonomous return to the start, with or without equipment

-

Remote control and instant operating data for operators

-

Bi-directional travel for maximum operational flexibility

This level of automation reduces manual handling and supervision, freeing up staff for other tasks and minimizing human error.

Energy Recovery and Battery Flexibility: Lower Costs, Higher Efficiency

A standout feature of these trolleys is their ability to recover energy during descent and use it for the ascent. This regenerative system reduces reliance on external power sources and cuts operational costs.

For installations with low elevation or higher power needs, interchangeable batteries provide flexibility and continuous operation. This means:

-

Lower energy costs due to self-recharging on descent

-

Reduced downtime with quick battery swaps

-

Fewer trolleys needed, thanks to efficient fleet management

-

Consistent performance across a range of installation types

Operators benefit from a more sustainable, cost-effective solution that adapts to their specific site requirements.

Enhanced Safety, Real-Time Data, and Simplified Procedures

Safety and operational transparency are at the core of automated zip line trolleys. These systems offer:

-

Real-time operating data for instant decision-making

-

Remote control for quick response to changing conditions

-

Automated speed regulation and braking for every ride

-

Compliance with recognized safety standards (EN 15567-1, EN 17109)

-

Simplified procedures that reduce human risk and error

By automating critical safety functions and providing operators with live data, these trolleys help maintain high safety standards while streamlining daily operations.

Product Comparison: Models and Customization for Every Operation

Automated zip line trolleys come in several models to suit different needs. Here’s a quick comparison:

| Feature | CONDOR Regen | CONDOR Boost | CONDOR Kids | THE BEAST Regen | THE BEAST Boost | LOADER |

|---|---|---|---|---|---|---|

| Certification | EN 15567 | EN 15567 | EN 15567 | EN 15567-17109 | EN 15567-17109 | No |

| Weight | 12.5 kg | 15 kg | 12.5 kg | 17 kg | 22 kg | 27 kg |

| Max Descent Speed | 90 km/h | 120 km/h | 60 km/h | 90 km/h | 120 km/h | 90 km/h |

| Max Climbing Speed | 80 km/h | 90 km/h | 30 km/h | 80 km/h | 90 km/h | 30 km/h |

| Automation | Autonomous | Autonomous | Autonomous | Autonomous | Autonomous | Semi-automated |

| Autonomy | 100 cycles* | Unlimited | Unlimited | 100 cycles* | Unlimited | Unlimited |

| Operator Dock | Automatic | Automatic | No | Automatic | Automatic | Manual |

| Speed Regulation | Yes | Yes | No | Yes | Yes | No |

| Pylon Passage | No | No | No | Yes | Yes | Yes |

| Interchangeable Battery | No | Yes | Yes | No | Yes | Yes |

| Remote Control | Yes | Yes | Yes | Yes | Yes | Yes |

| User Weight Range | 35-130 kg | 35-130 kg | 10-45 kg | 35-130 kg | 35-130 kg | N/A |

| Tandem Option | Yes | Yes | No | Yes | Yes | No |

Optional features include:

-

Two-seater spreaders for tandem rides

-

Ski racks for winter operations

-

Lying position extensions for unique experiences

-

Winches for lifting test weights

Each model is designed for easy installation, with automatic departure docks, integrated braking systems, and maintenance contracts to ensure continuous operation.

Warranty and Long-Term Rental: Predictable, Worry-Free Operations

Every trolley comes with a one-year or 6,000 km primary warranty package, including:

-

Initial operator training

-

Remote maintenance assistance

-

Standard trolley replacement for critical failures

-

Wear parts provision and restocking

-

End-of-warranty maintenance and inspection

Starting in 2025, a long-term rental option will be available, offering all warranty services for an annual fee equal to 20% of the new trolley price. This model gives operators:

-

Predictable, transparent costs

-

Reduced operational expenses (personnel, maintenance, transport)

-

Access to the latest technology without large upfront investments

Conclusion

Bi-directional, autonomous zip line trolleys are redefining what’s possible for adventure and recreation operators. With energy recovery, real-time data, and advanced safety features, these trolleys deliver operational efficiency, cost savings, and a superior guest experience. Investing in this technology means fewer manual tasks, lower risks, and more time to focus on growing your business.

FAQs

How do bi-directional zip line trolleys improve operational efficiency?

-

Automate return and dispatch in both directions

-

Reduce manual labor and supervision needs

-

Provide real-time data for better decision-making

What are the main safety features of these trolleys?

-

Automated speed regulation and braking

-

Compliance with recognized safety standards

-

Real-time monitoring and remote control

Can these trolleys operate in different weather conditions?

-

Yes, they are designed for a wide range of temperatures and wind speeds

-

Weather-resistant components ensure reliable performance

How does the energy recovery system work?

-

The trolley stores energy during descent

-

This energy is used to power the ascent, reducing external power needs

What options are available for customization?

-

Interchangeable batteries for low elevation or high power use

-

Two-seater and lying position extensions

-

Custom branding and accessories

Seeing the business opportunity in Autonomous Bi-directional zipline trolleys?