This whitepaper on retraction that outlines other potential external and internal influences on retraction, how to inspect for them, and most importantly, how to orient participants to properly use TRUBLUE Auto Belay devices safely.

TRUBLUE retraction systems overview

Two distinct features are integrated into the TRUBLUE Auto Belay's design: a cutting-edge self-regulating brake mechanism and an automatic webbing line retraction system. Children and adults can utilize the innovative braking mechanism for a smooth fall with little variation in descent speed, while climbers can use the retraction system to tighten the webbing as they ascend a route.

TRUBLUE retracts the webbing inside our products using a power spring that is fittingly dubbed a retraction spring. The retraction spring continuously adjusts to a climber's actions as they ascend the wall, resulting in the smoothest, most attentive belay conceivable.

Recognizing retraction risks and obstacles

The possibility of creating slack in the webbing line is a common worry when using an auto belay. External factors are the main cause of excess slack development, however broken interior parts can also cause a jammed or otherwise clogged retraction system. In a TRUBLUE device, retraction and braking work separately from one another, but if a climber slips on webbing that has collected slack, the braking system won't work until the slack is taken out of the system.

The only recorded slack-related injuries have been brought on by outside sources despite the fact that over 40,000 TRUBLUE Auto Belays have been erected and millions of descents are made every day. As of right now, we are not aware of any accidents involving harm to internal parts like a retraction spring. Therefore, in order to effectively prevent each from providing a risk to users, it is crucial to further understand how external influences, in addition to internal considerations, can impact the retraction mechanism.

External variables that could obstruct or inhibit retraction

When an auto belay is in use, a number of external causes may cause slack to be introduced into the webbing line. Following the suggested Inspection & Maintenance plan found in the TRUBLUE Operator Manual can help to mitigate some of these problems while mitigating others that are the consequence of user mistake.

If the webbing line gets tangled up with sticking handholds, climbing wall features, or climbing gear when climbing normally, slack can be added. If the user continues to ascend above this point of restriction, further slack may form, increasing the risk of a hazardous fall.

For outdoor climbing setups, accumulated debris or foreign items that become stuck in the nozzle of the auto belay might make it difficult to retract the rope. Even indoors, enough hair, dirt, or excessively frayed webbing can clog the nozzle and either hinder or stop retraction.

What to do if the webbing line develops slack

Preventive measures are the best method for reducing slack risk brought on by external variables. These tasks include instructing users on how to test the retraction mechanism before climbing, carrying out suggested periodic maintenance, inspecting the device and webbing, and recertifying annually.

Climbers should try to downclimb as much as they can before releasing go of the wall if slack does develop in the webbing line for the reasons outlined above. It is safe to let the brake mechanism drop the climber the remaining distance to the ground once the slack has been taken out.

If the webbing line becomes tangled with a hold or other piece of climbing gear, the climber should immediately stop ascending and either flick the webbing line free (similar to how you would adjust the rope when top-roping or lead climbing) or descend to the ground by downclimbing or allowing the braking system to work.

All owners and operators are required to create an emergency rescue plan for any climber who is in trouble, as indicated in the TRUBLUE Operator Manual, and to share that plan with climbers as part of safety orientation.

Advice for preventing external problems

We strongly advise that facilities make it a requirement for all auto belay users to successfully complete an obligatory orientation on the safe use of the auto belay in order to better recognize and respond to external threats. The Climbing Wall Association has laid out standards for what should be covered in a typical auto belay orientation, including the identification of inherent dangers, in the CWA Auto Belay Position Paper. You can find these instructions here: CWA Auto Belay Position.

We also advise route setters to avoid installing extraneous gear in an auto belay's path if possible to minimize the potential for obstructions to obstruct optimal retraction.

Regular inspections and adherence to periodic maintenance needs will lessen the possibility of extraneous objects impeding retraction. The TRUBLUE Operator Manual, which is available on our website, contains comprehensive descriptions of how to correctly execute each type of inspection, including assessing and evaluating webbing wear: Product Guides

Both climbers and operators should be trained, aware of the risks associated with building up slack, and test each equipment before usage to make sure it is working properly before the climber leaves the ground. Anyone should never climb on a machine that isn't retracting properly.

Problems with internal retraction mechanisms

We are not aware of any reported injuries caused by a damaged retraction spring out of the 40,000+ devices and millions of daily descents.

Even the best-designed retraction springs may endure a short lifespan because to the high cyclic use that an auto belay experiences. Users of the TRUBLUE Auto Belay benefit from greater security because the retraction and braking mechanisms are kept separate from one another. Stop using right away in the unlikely event that a retraction spring sustains damage in-between yearly maintenance visits.

The auto belay's inability to take up slack in the webbing is the most visible sign of a damaged retraction spring. If enough downward force is given to a first-generation TRUBLUE with a damaged retraction spring, the webbing may come unspooled. Unspooling shouldn't take place while a climber is ascending because it needs to exert this downward force. Furthermore, the autonomous braking system will continue to work even in the absence of retraction, offering a safe and controlled rate of fall after the apparatus has been weighted.

What to anticipate in the event that a retraction spring fails while in use

A climber may hear a popping sound if the retraction spring breaks while it is in use, and they will notice that the tool is no longer eliminating slack from the webbing line. The climber should immediately cease climbing and either downclimb or let go of the wall, enabling the brake system to drop them back to the ground, rather than studying this problem from a high position. A retraction spring is more likely to fail while the climber is descending than ascending since pressure is applied to the device during descent and is absent during ascent. It is still safe for the climber to descend in either scenario because the braking system operates independently of the retraction spring.

Operators should tell climbers to descend promptly, without tugging on the webbing, if they encounter retraction problems mid-climb.

Although there have never been any injuries attributed to retraction springs, it is legally forbidden to continue climbing on an auto belay while the retraction spring is damaged.

Taking preventative measures to avoid internal damage

Unusually high cycle counts, harsh environmental conditions, regularly operating devices above the maximum mounting height or otherwise stretching the webbing line beyond the maximum capacity, and subjecting devices to significant drops or impacts are all contributing factors to premature damage to the retraction system. Furthermore, uncontrolled webbing retraction can seriously harm the internal parts of the TRUBLUE SPEED due to the increased tension needs for speed climbing.

The TRUBLUE Operator Manual provides instructions on how to execute scheduled maintenance, including frequent inspections, as well as how to make sure that every auto belay obtains a routine annual recertification. In the odd event that a retraction spring does sustain damage in between yearly maintenance visits, the affected auto belay needs to be taken out of service right away and sent in for repair.

Conclusion

All TRUBLUE devices must perform webbing retraction as a fundamental feature. Webbing retraction is handled by the retraction spring, which is a very dependable part. If a device is experiencing retraction problems, there are several elements to take into account, and the aforementioned steps should be followed to identify and maybe treat some of the underlying causes.

Auto belay users should be made aware of the potential causes of excessive slack in the webbing line as well as the precautions to take in order to prevent it or, in emergency situations, respond to it.

All facilities should also read the CWA Auto Belay Position Paper and adhere to the Inspection & Maintenance guidelines outlined in the TRUBLUE Operator Manual.

A list of the duties and responsibilities of an operator

- Completion of the required auto belay orientation is required for all users. The CWA Auto Belay Position Paper contains instructions for conducting an auto belay orientation.

- For each climber in need, operators must come up with an emergency rescue strategy.

- As stated in the TRUBLUE Operator Manual, operators are in charge of performing routine device inspections and following the guidelines for scheduled maintenance.

- Operators should urge the climber to descend right away without pulling or otherwise introducing slack to the webbing line in the unlikely event that a retraction issue should emerge while the device is in use.

- Avoid climbing on any equipment that isn't retracting properly. Remove the device from rotation right away and send it in for service if appropriate retraction isn't happening.

Additional expert Information regarding Auto Belay technology

Interested to read more about the Auto Belay technology and expert opinions?

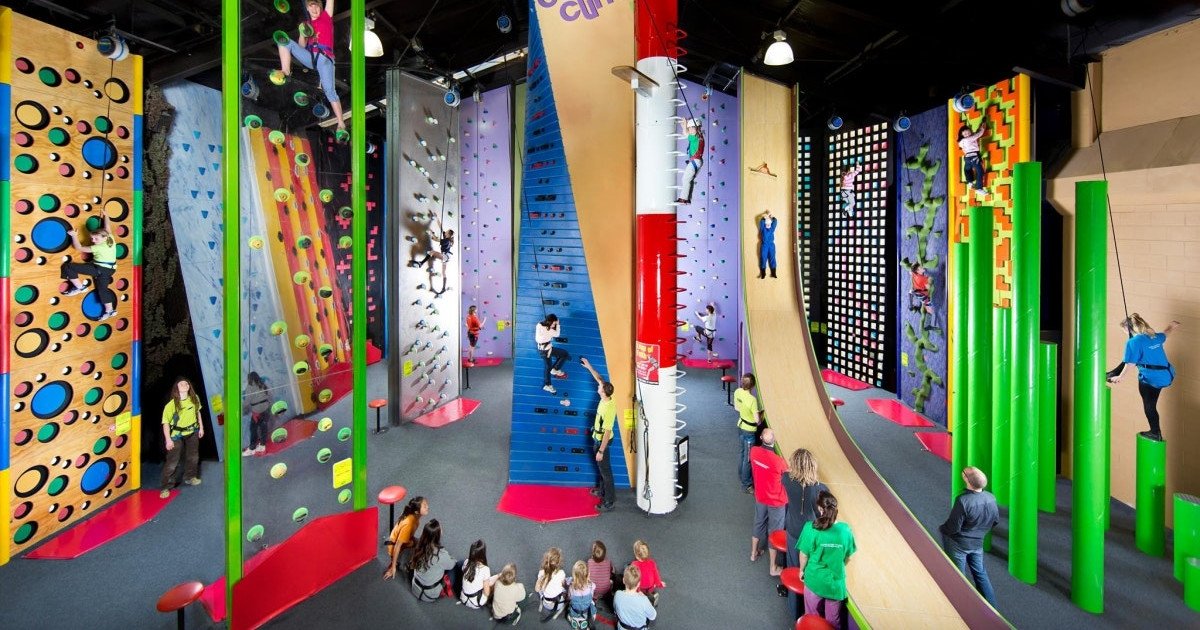

- Why More FECs Trust TRUBLUE Auto Belays

- TRUBLUE iQ+ World's first catch-and-hold auto belay

- Climbing Walls at FECs: ROI Considerations

- Improve the Accessibility and Inclusivity of Your Climbing Gym

- Catch-and-Hold: What is it and how does it work?

- Climbing on Auto Belay: What You Need to Know

- Our Auto Belay Maintenance Program

- 7 Ways Magnetic Braking Is Better Than Friction

- A Kid’s Guide to Gym Climbing

- Climb Safe, Climb Smart: Understanding the Auto Belay Device

- 5 Ways TRUBLUE Can Help a Climbing Gym

- Auto-Belay and hands-free climbing challenges

- Auto Belay for Speed Climbing

- Speed climbing is becoming more popular then ever

- 5 unique ways to use an auto belay

- Trustworthy and Consistent Climbing Protection

- Auto belay retraction systems white paper